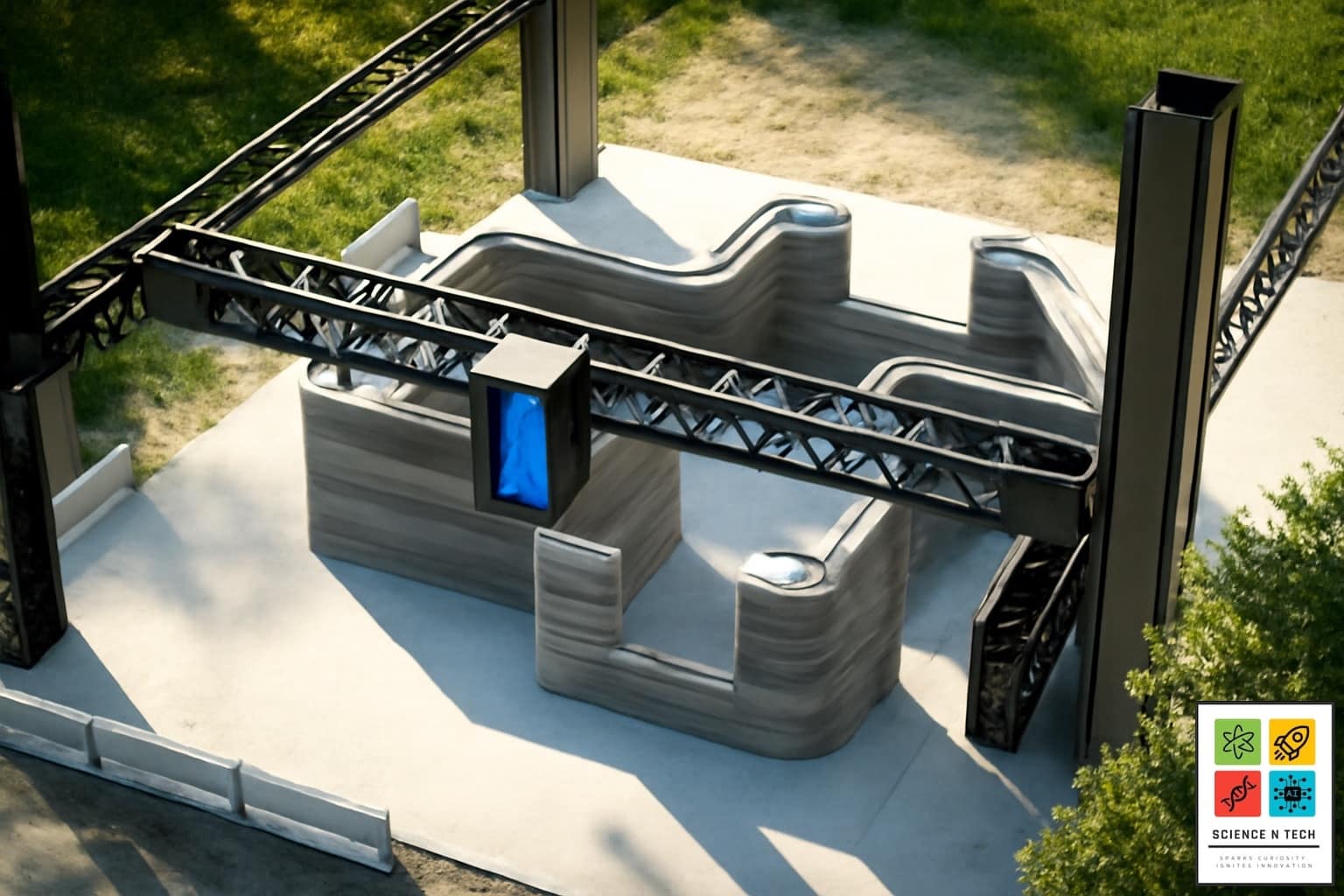

Think of a traditional construction site: a chaotic orchestra of noise, dust, and heavy machinery, where a small army of workers spends months, or even years, meticulously assembling a building piece by piece. It’s a process that is notoriously slow, expensive, and wasteful. Now, picture a different scene: a quiet site where a single, giant robotic arm methodically glides back and forth, extruding perfectly placed layers of concrete. Within days, the walls of a house materialize from the ground up, built by a tiny crew with minimal waste. This isn’t a scene from a futuristic movie; this is construction 3D printing, and it’s a real-world technology that is starting to disrupt one of our oldest industries.

Table Of Content

How Do You Print a House? The Technology Explained

At its core, construction 3D printing is a form of additive manufacturing. Instead of cutting materials away to create a shape (like a sculptor), you build an object from the ground up, one layer at a time, guided by a digital design.

The process begins with a 3D model created in a CAD (Computer-Aided Design) program. This digital blueprint is then fed to a massive 3D printer on the construction site. These printers typically come in two main types: a gantry system, where a print head moves along an overhead frame, or a robotic arm, which offers more flexibility.

The “ink” for these printers is a high-tech, proprietary concrete or mortar mix. This isn’t your standard cement. It’s a precisely engineered goo that is fluid enough to be pumped through a nozzle but viscous enough to hold its shape and support the weight of the next layer without slumping. Developing these advanced materials is one of the biggest areas of innovation in the field.

Once the machine is set up, it begins its methodical work, extruding the concrete mix in long beads to trace the outline of the walls. Layer by layer, the structure rises from the foundation. The process is incredibly fast—what might take a team of masons weeks to build with cinder blocks can be printed in as little as 24 to 48 hours.

The Blueprint for a Better Build: Key Advantages

This new way of building offers a powerful solution to some of the biggest problems plaguing the traditional construction industry.

Speed and Efficiency: The most dramatic advantage is speed. By automating the wall-building process, construction timelines can be slashed from months to weeks.

Reduced Cost and Labour: With a smaller crew needed to operate the printer and less time on site, labour costs can be significantly reduced. This helps address the chronic labour shortages facing the construction industry in many parts of the world, including here in Australia.

Sustainability and Waste Reduction: Traditional construction is incredibly wasteful, producing tons of off-cuts and excess material. A 3D printer is precise, using only the exact amount of material needed for the structure. This can reduce construction waste by up to 90%, making it a far more sustainable method.

Architectural Freedom: Because the printer is guided by a digital file, it can create complex, curved, and organic forms just as easily as straight lines. This frees architects from the “tyranny of the straight edge,” allowing for more creative, beautiful, and structurally efficient designs that would be prohibitively expensive to build with conventional methods.

From Foundations to Finished Homes: Real-World Applications

Construction 3D printing has moved well beyond the experimental stage and is now being deployed on real-world projects.

In the United States, the company ICON is a major leader, having built entire communities of 3D-printed homes in Texas and partnering with non-profits like Habitat for Humanity to provide affordable, resilient housing. Their technology has proven to be particularly effective for creating durable homes quickly for communities experiencing homelessness or recovering from disaster.

The technology is also gaining traction here in Australia. Sydney-based company Luyten has been developing 3D printers for construction, showcasing their ability to build structures and even working on projects for the Australian Defence Force. These local developments signal that the technology is becoming a viable option for tackling our own housing affordability and construction challenges.

A surprising fact: This technology is not just for Earth. NASA is actively funding research into 3D printing technologies to build habitats on the Moon and Mars. It would be impossible to ship all the building materials needed for a colony from Earth, so the plan is to use 3D printers that can build structures out of the local lunar or Martian soil (regolith), mixed with a polymer binder.

While single-family homes are the most common application, the technology is also being used to print everything from bridges and skate parks to artificial coral reefs designed to help restore marine ecosystems. The possibilities are expanding every year.

3D printing won’t completely replace traditional construction overnight. But as the technology matures, it presents a powerful, disruptive tool. It offers a faster, cheaper, and greener way to build, with the potential to address some of humanity’s most pressing issues. As these printers become a more common sight, we are fundamentally changing how we build our world. Could this technology be the key to solving the global housing crisis and creating more sustainable cities for the future?

References

- ICON. (n.d.). 3D Printed Homes. Company Website.

- NASA. (2022, September 29). NASA’s 3D-Printed Habitat Challenge.

- Luyten 3D. (n.d.). Official Website.

- Note: An Australian company at the forefront of construction 3D printing technology.

- Link: https://www.luyten3d.com/

- COBOD International. (n.d.). 3D Printed Buildings. Company Website.

- Note: A leading global provider of construction 3D printing technology.

- Link: https://cobod.com/3d-printed-buildings/

- Massey, A. (2023, April 14). What Is 3D-Printed Architecture? Architectural Digest.